Industry > Refining Sugar

Refining Sugar

In the 1860s and 1870s, when cane sugar was grown in northern Australia and in Fiji, it was possible to extract sugar roughly from the molasses, but this sugar contained impurities including molasses, giving it more colour (and impurities) than the white sugar which is now consumed in households. As tastes changed, refining became vital. “A Queenslander” analysed the issue in 1874:

RAW SUGAR OR REFINED ?

Argus 13 November 1874

[Until the 1860s “ration sugar” was imported from the Phillipines, China, India, and Mauritius]

There is strength, often in the form of animal life, but it is not the sort of strength that is desirable in sugar.

From the beginning of sugar making in the colonies a better quality was aimed at. At the outset, when a couple of rollers of wood, moved by a hand lever or by a horse, and any sort of pots for boiling, were considered sufficient for making sugar, some queer stuff was produced. It was sticky, dark, soft, and burnt occasionally; but it was clean… With better machinery other makers produced a superior article. The quality of the sugar improved rapidly, and the taste for the better article improved with it…

In the towns demand for still whiter sugar continues, and the price for white, firm, hard crystal is sufficiently high to induce makers to aim at the highest quality they can…

The use of charcoal or char is the line that divides raw sugar from refined. This is made from bones and is expensive. The bones are heated in retorts until the animal matter is expelled. The remains form a porous substance that has powerful decolorising properties. It extracts the last trace of coloring matter from sugar juice, and leaves it as colorless as pure water…

There is no hope whatever that loaf sugar can be made without refining; without passing the juice through animal char… At present there is no more loaf sugar used than twenty years since… The difficulty of dividing loaf sugar at the table and giving each the precise quantity wanted has been an obstacle to its common use. It is now out of fashion, and there is no probability of an increased demand.

Enter the Colonial Sugar Refining Company, building refineries and scouring Europe for expert chemists and engineers.

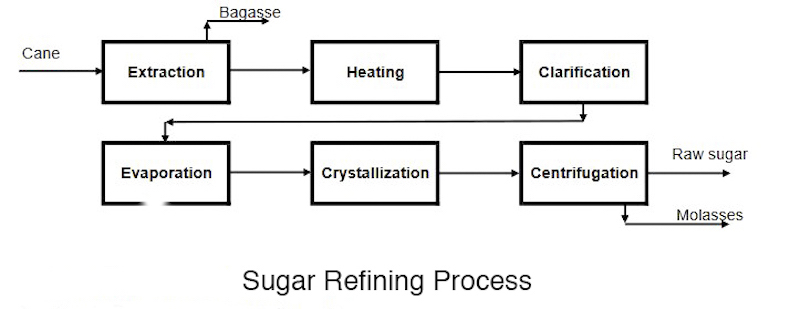

Raw sugar (98% sucrose) must be refined (to 99.9%) to create crystalline white sugar and the other forms (syrup, treacle, molasses, tablet) in which sugar is sold. Water, ash, organic matter and other sugars are removed to purify the product and prevent its deterioration. These impurities are small but elusive: they require hot-water washing, adding and removing lime, carbon dioxide and bone charcoal, filtering, boiling in a near-vacuum, warm air drying and sieving.

In the traditional refining process, raw sugar was first mixed with heavy syrup and centrifuged to wash away the outer coating of the sugar crystals. The remaining sugar was then dissolved to make a syrup, which had to be clarified by adding, then removing, a variety of chemicals. Colours were then removed from the clarified syrup by filtration: the purified syrup was then concentrated and crystallised under vacuum to produce white refined sugar.